What makes our LED profiles special

Everyone can say that their product is the best. We do not want to only say so but to prove you, step by step, why our products are “the best of the best”.

European products,

European production only!

All our products are 100% of polish origin. We produce all profiles and components in Poland/EU. It is a reason why we manage to control over the quality of the production on every stage. European production standards are much higher then those in factories located in China, thanks to the European production norms taken as the standard in whole Europe, due to the implementation of the same law. As a result we receive the highest quality product, protected by 2 years guarantee.

When the distance is smaller, the communication is easier and reaction and delivery are faster. Thanks to the fact that our countries are close to each other, transportation is relatively cheap, especially comparing it to the oversea shipments, which cost thousands of euros and take long weeks.

To meet expectations of our customers we decided to cover the shipment charges and to offer to many of our customers a free transportation or low rate for the next day delivery via AIR shipment. Our reaction time for purchase orders is immediate and the delivery time from our warehouse to your door is usually between 1 to 3 working days.

The communication with us is simple and efficient. We keep large stock of all our products, so you do not have to invest in a large supply or purchase a MOQ each time. We relieve you from the stress about the security of the transactions and cost of the currency exchange EUR/USD, fluctuation and risk coming from unstable exchange rate. Our company has 10 years of experience in cooperation on the international market so you can have a full confidence in working with us. By choosing our products you choose the European quality and after all, you support the European economy.

Our R&D department, heat dissipation analyses and light distribution optimizations:

Our company employs experienced lighting engineers who take care of development of our new products design, OEM production, preparation of tools and full documentation for a forthcoming production.

We are constantly working on new designs and new applications to expand our offer. Working with us will make you keep a high position on the market of innovatory and competitive lighting products. With our quality service you will have a full support and access to new products, new technologies and new ideas. We create the future products and create the market. Our products will build your position between the competitors. Our products can be developed and produced under OEM condition. We are open to your propositions, the new ideas, which we can bring to reality.

Before our designs will reach the production stage, they must pass important tests, which verify the design conception in many ways.

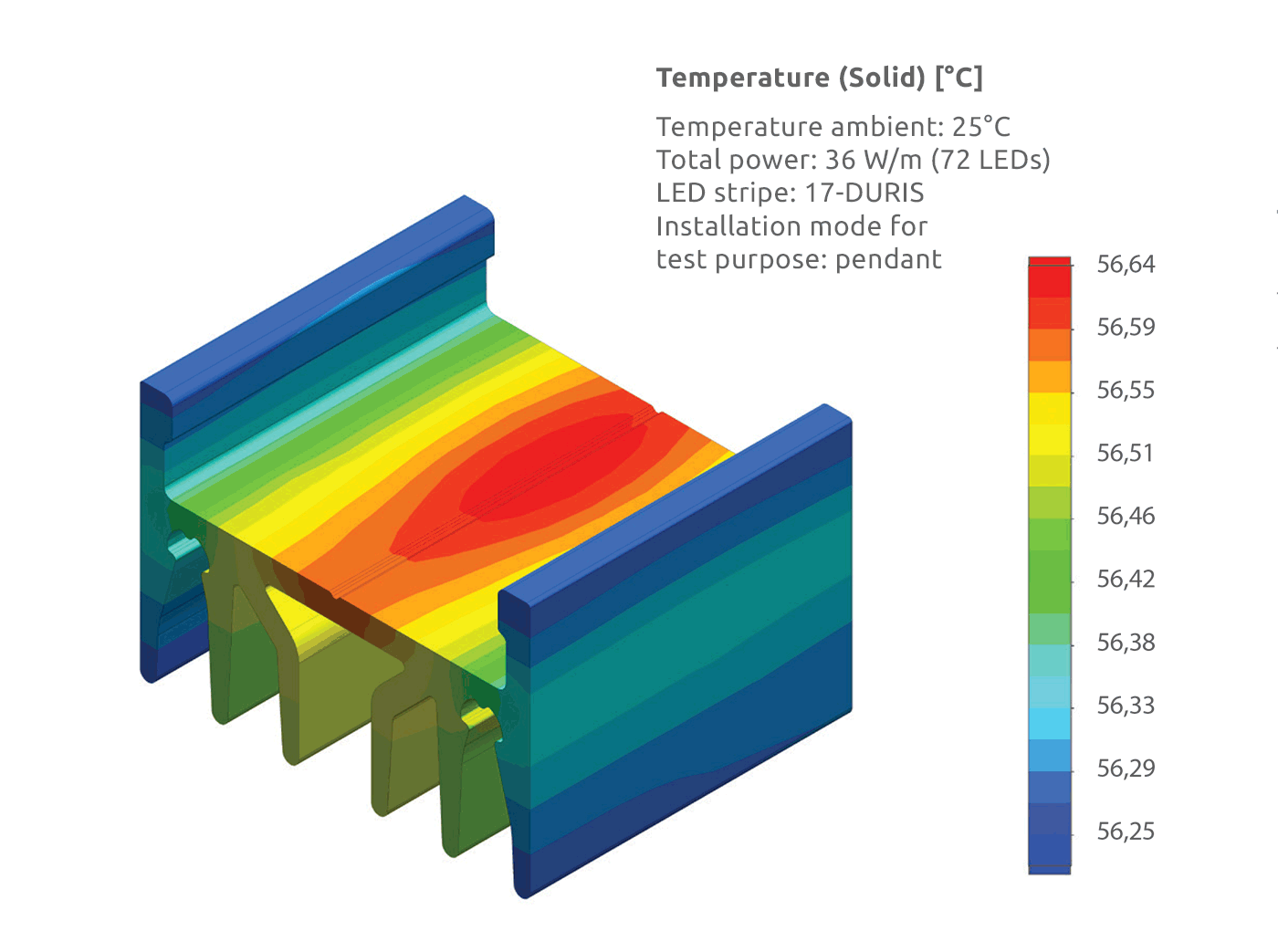

We perform detail manufacturing analyses such as thermal management, heat dissipation and a light distribution to make sure about the ability of the product to dissipate the heat in certain load and certain environment conditions, considering all the aspects. Those technical possibilities help us save time and money and assure that the design after production will meet all the requirements. It helps us to optimize the relation between LED power (heat dissipation), the weight and shape of the profile. From one side it is related to the production cost and from the one is connected with the operating temperature and the lifetime of the LEDS. Those important issues cannot be accidental. We guarantee that this will stay under our control during the whole process and the efficiency will be the proof when the product will become real.

You may notice many products on the market, which look like a "shell”, not like a real heat sink. The amount of aluminium used for their production is not big enough and the profile is only imitating the original product by its similar shape. The parameters between our profiles and many other products available on the market, that has a similar shape, are not comparable. When the weight of the profile is bigger, as in case of our products, they perform much better: the heat is taken away faster.

The "imitations" are not supported by any analyses: wall thickness of the profile and a low aluminium weight is driven by a low cost. Buying the profile produced with a minimum weight of aluminium in the end will cost you more then a purchase of original products. The lifetime of the LEDs will be reduced due to its higher operating temperature. You may notice that the lifetime of LEDs specified by many producers is given for an ambient temperature of 25’C then the lifetime is rated to 50 000h. This is an unrealistic parameter to reach in a normal operating environment. The heat produced by the LEDs will be much higher then Ta=25'C and the same the lifetime of the LEDs will be lower, lower then 50 000h which has been used very often as the marketing point or part of the guarantee. How to prolong their life then?

To slow down this process you need to use an efficient heat sink, which weight and heat dissipation capability will be properly selected and calculated against the power load of the LEDs.

Only that will save your money and prevent the future failures of the LEDs. Do not let it happen, ask us for advice and analyses which we can perform on our profiles with yours LEDs.

Conclusion: The profiles production, their selection and the problem of heat dissipation are an important issue, which should be left to professionals. Using products which cannot be supported with any analyses and which only imitate the real heat sinks is dangerous to LEDs. Low cost reduces the lifetime of the LEDs and frequently causes failures, which may happen more often and faster then expected. The exchange, service of damaged LEDs is few times more expensive then a purchase of a proper heat sink.

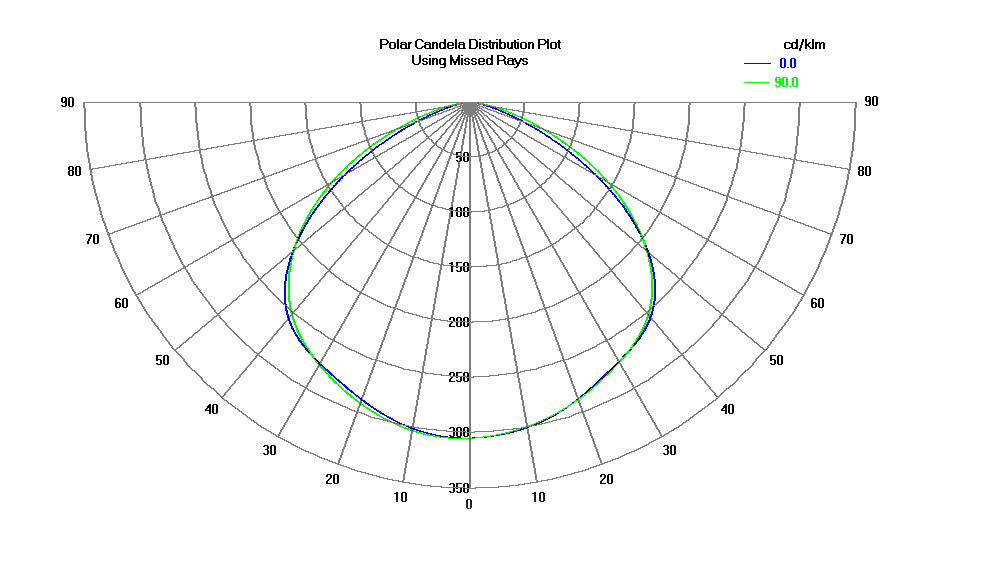

Lighting rays analyses and the optimization of the efficiency. Without it we walk in the dark.

After the thermal analyses and a selection of a proper heat sink we have to influent the second important parameter, which is the light efficiency of the LED luminary.

As you may notice not so many producers pay attention to that and those who do, make lamps 10-15% more efficient as the final result of that process. The proper internal shape is optimizing to the minimum the internal light rays bouncing inside the profile. In other words the luminaire is brighter because more light is delivered to the surface and the light is bringing more energy because the rays haven’t bounced many times before reaching the surface. This important aspect of bouncing of the light inside the led chamber make a big difference and helps reduce the energy and power consumption because lower power LEDs can deliver the same effect (flux) as they normally achieve in a higher load of the power. It is critical to choose the right heat sink but the choice of a product with an optimized light distribution helps to reduce the initial power and meets the requested brightness with a smaller power load. The proper light distribution helps the light to reach the surface without an unnecessary and unwanted bouncing. As a result we get a brighter luminary with smaller power consumption.

All those elements are the necessary steps, which we need to take care of, when we design and produce the LED lamps.

The ray distribution analyses and Lambda Polar diagram present the angle and the value of the luminaries lighting. All files are presented on our website to help you to choose the right product for your project.

In our tests and optimizations we used for each LED profile, our dedicated LED stripes that fit to the reserved space perfectly. However we can build a 3D model of any LED stripe you would like to use with our LED profiles basing on the information as spacing and detailed LED input data and perform tests on your, different LEDs. Calculations takes some time but as a result we have the possibility to produce *.IES files which are necessary and requested by the architects as the future input data for the rooms lighting calculations.

Please find our *.IES files, ready to download for each product that we offer.

The influence of a right selection of the aluminum alloy and lifetime of the LEDs

The right density aluminum alloy has not only different strength parameters in normal use but it also has different heat dissipation parameters. The aluminum alloy has heat dissipation ability on level of 200-230 W/(m'K), where the pure aluminum has that parameter on level 230W/(m'K). Choosing the right aluminum alloy is very important because this parameter influent on the heat dissipation performance of the LED profiles and operating temperature of the entire luminary.

If we simplify the category of the aluminum alloys to two and sort them out by density we can say that we have a "soft" aluminum alloy, which should not be used for cooling, and a” high density" aluminum alloys which internal density is higher and cooling will be faster and more efficient. When we look at different alloys of aluminum at the microscope we will notice that some of them looks like a” Swiss cheese" with a lot of holes, empty spaces, air pockets which work as an isolator. The density and the cooling capability are lower, as well as the weight. Obviously they are not the best option for cooling purpose.

However there is some aluminum alloys which can be extruded and anodized and have a density higher then average and higher heat transition parameters. In other words we can say that those alloys are dedicated to cool down the electronic components due to the special parameters which are much higher then in the a soft aluminum alloy.

The conclusion is that the profiles are not equal when we consider the heat dissipation parameter even if they look the same. The heat dissipation may be poor due to the wrong aluminum alloys selection. Please remember that only well selected alloys should be used for the heat dissipation and the LED profiles production.

Working with us will put that problem away because we are working with aluminum for years and we know everything about it. We produce and supply only top quality aluminum products, which are dedicated for the heat dissipation of the LEDs. Working with us is a guarantee that you will receive original quality products with the highest heat dissipation performance possible to receive from the material called aluminum. We use certified material from a documented source, so the speculation and the risk that someone supply us a different alloy is reduced to zero.

Anodizing process of the surface to protect against corrosion

LEDsON products are known from their top quality finish of the anodized surface, which is FREE of any extrusion marks, the texture is deep and with a very fine finish. The deep anodizing of the profiles preserve the quality for years, protect the aluminum against corrosion, extend durability and provides more resistance to the scratches during transportation or handling. We adopt German quality and parameters of the anodizing process as a standard for our line of products.

Unfortunately on the market there are many cheap products with surface defects, full of scratches and with a very shallow anodizing surface. For some buyers they may look fine unless they compare them to the real quality products. Fine, deep anodizing process takes time, and time means money, so it is important to understand the difference between some products and its relation to their final price. As our strategy and our goal, we chose to produce the highest quality products, dedicated for a heat dissipation, which cost more but are more efficient and more durable.

Durability of the diffuser’s color and the light efficiency

We produce our lighting diffusers from certified material form world leading chemical suppliers such as Buyer or GE. The material is UV stabilized, dedicated for LED lighting and meets the market highest standards. The light transition (efficiency of the lamp) depends on many aspects of the material that has been used in the production such as density, color master and thickness. Our products were designed and tested to achieve a high transition rate. The material is free of any inclusions or scratches over the surface. All our products are produced under a very tight tolerance so the fit of the elements is perfect.

Aluminum accessories, it makes different as day or night

All our products at the design stage are made with the idea of the dedicated accessories. We not only design and produce profiles but we design and produce the aluminum accessories at the same time when we design and launch new products to the market. We provide a complete lighting solution with an idea how to use to it to make it work and to look aesthetic and stylish at the same time. Our goal is to deliver a complete product, a product that has more than two applications, which has a unique design and which is a piece of art itself. Installation should be as simple as possible. With our components, and their full technical documentation available online, the lighting installation will be simple. All our accessories are in matching color with a very fine precision of the finish. We produce many different kinds of components for our profiles, but the most popular are aluminum end caps, aluminum linear and angle connectors, arms and mounting brackets. A use of the profiles with aluminum accessories delivers a better visual appearance.

In a longer perspective, a use of aluminium components is more advantageous because the aluminum is aging slower than the ABS or plastic they may be made from. Using aluminum components will take away the problems with a shrinking process, not matching colors, a change of the color or a loss of the grip of the elements over the time. We always offer a full set of aluminum components to choose from for all our profiles. Please have a look on our wide range of products to check it out.